crushing and beneficiation flowsheet of iron ore processing plant

2020-01-11T16:01:26+00:00

Iron Ore Processing Flowsheet Grinder Process

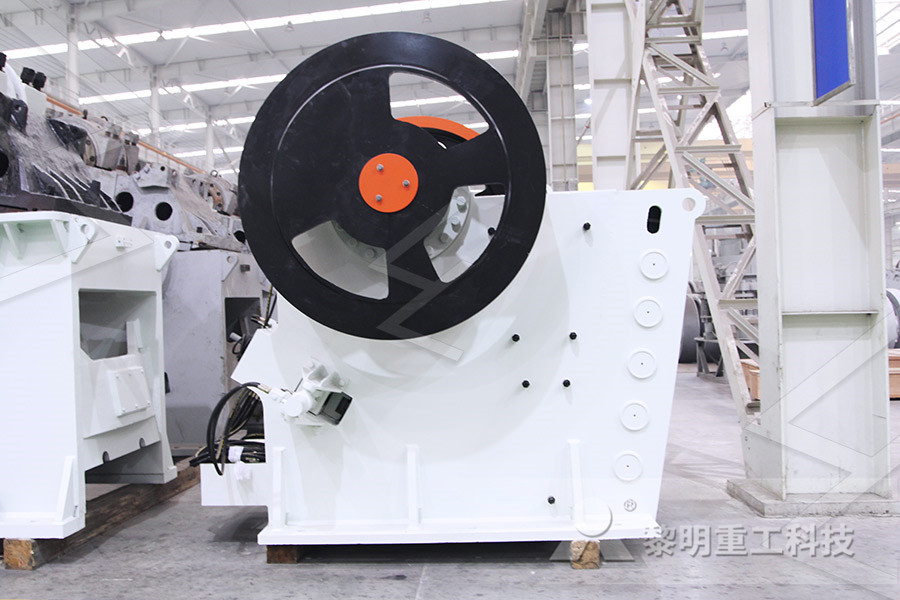

The iron ore processing flowsheet is consists of two processes:Dry Processing and Wet Processing The primary beneficiation plant consists of only a jaw crusher and from there the material is transferred to the secondary plant via conveyor belt methodIn fact, the iron ore process flow goes as follow: Firstly, raw iron ore is exploded in the iron ore mines; Then vibrating feeder will feed iron ores to the iron ore primary crusher crushing cavity, where large size raw iron ore is going to be resized into iron ore sandIron Ore Processing Flowsheet hotcrusher3/4/2014 For beneficiation of a particular iron ore the emphasis is usually to develop a cost effective flow sheet incorporating necessary crushing, grinding, screening and beneficiating techniques which are necessary for the upgrading of the iron ore A typical flow sheet for iron ore beneficiation plant Beneficiation of Iron Ores – IspatGuru

Iron Ore Leaders in Mineral Processing Worldwide

Having developed an effective and optimised flowsheet, you need a plant that safely and effectively applies this flowsheet to the ore body to extract high grade iron ore whilst delivering high availability, with low capital and low operational expenditureProcessing plant The processing plant consists of six individual scrubbing, screening and desanding circuits The wet scrubbing units are used to break down the sticky clays attached to the ore, into a fine suspended clay fraction suitable for subsequent wet beneficiation Beneficiation is the process of separating the valuable material from theProcessing plant Roy HillIron Ore Beneficiation Process 1 Iron ore initially through the jaw crusher, a reasonable size of crushed, by lifting machine, feeder evenly into the ball mill, crushing, grinding method After ball milling iron ore fine material into the next procedure: classificationIron Ore Beneficiation Plant,Iron Ore Crusher Machine

The Latest Developments in Iron Ore Processing

–Process 600t/h lumpy iron ore • DMS Cyclone –Only 6mm material for iron ore –360mm diameter cyclone –Process 40t/h per cyclone • Larcodems –90+6mm stones –12m diameter –Operating capacity of 600800t/h –Efficient separation at SG’s as high as 41g/cm3 Dense Media Separation on Iron Ore •Iron Ore Processing Flowsheet GrinderProcess Theiron ore processing flowsheetis consists of two processes:DryProcessing and Wet Processing The primarybeneficiationplant consists of only a jaw crusher and from there the material is transferred to the secondary plant via conveyor belt methodiron ore beneficiation dry process flow sheet Industar Beneficiation of iron ore process flo the iron ore beneficiation process flow includes iron ore crushing and flotation this passages tells you how to produce iron ore concentrate and the iron ore contact us beneficiation of iron ore slimes crushing, grinding and miningIron Ore Beneficiation Process By Slimes Sale Crusher

Beneficiation of Iron Ore jxscmachine

The ore dressing technology of iron ore mainly has feeding, crushing, washing, sieving and magnetic separation process, the iron ore processing equipment are including vibration feeder, trommel scrubber washing machine or log washer or trommel screen, 23 Processing of Iron ore in India 8 24 Slimes of Iron ore 11 3 BENEFICIATION PLANT STUDY OF NOAMUNDI IRON ORE MINE 14 Fig 31 Overview of the main steps involve at primary crushing plant 16 Fig 32 Figure showing the Grizzly and Gyratory crusher 17 Fig 33 Conveyor at BENEFICIATION OF IRON ORE National Institute of Iron ore is the key raw material for steel production enterprises Generally, iron ore with a grade of less than 50% needs to be processed before smelting and utilization After crushing, grinding, magnetic separation, flotation, and gravity separation, etc, iron is gradually selected from the natural iron oreIron Ore Processing,Crushing,Grinding Plant Machine Desgin

Iron Ore Processing Plant Shanghai Company

The current iron ores beneficiation plant generally through the crusher crushed the raw ore, and then into the ball mill smashed through the gravity separation, flotation, extracted from the concentrate and tailings, and through chemical methods, and iron ore beneficiation products eventually become finished products–Process 600t/h lumpy iron ore • DMS Cyclone –Only 6mm material for iron ore –360mm diameter cyclone –Process 40t/h per cyclone • Larcodems –90+6mm stones –12m diameter –Operating capacity of 600800t/h –Efficient separation at SG’s as high as 41g/cm3 Dense Media Separation on Iron Ore •The Latest Developments in Iron Ore ProcessingCrushing and screening is typically the first step of iron ore beneficiation processes In most ores, including iron ore, valuable minerals are usually intergrown with gangue minerals, so the minerals need to be separated in order to be liberated This screening is an essential step prior to their separation into ore product and waste rockOre Beneficiation an overview ScienceDirect Topics

iron ore bedding and blending process « Mining

RSP's Ore Bedding Blending Plant (OBBP) has a base mix preparation track hoppers), iron ore crushing and screening system, raw material storage yard, rod Apart from a computerised LD process which has enhanced shop capability, »More detailed Modeling Sintering Process of Iron Ore – InTech In this chapter, a methodology for simulating the sintering process of iron ore is Metallurgical ContentBarite Beneficiation FlowsheetBarite Ore Crushing SectionGrinding and Barite Flotation SectionMining Methods Barite RecoveryOpen Pit Barite MiningUnderground Barite MiningGeneral Considerations Barite (barium sulphate) often occurs as large veins or beds, as gangue mineral in various mineral veins, in limestones, sandstones and like deposits The ores are generally Barite Beneficiation Process and Plant FlowsheetIron Ore Efficiently remove silica and alumina contamination to increase efficiencies in steel production Our iron ore wet processing plants are proven to successfully deal with silica and alumina contamination in the iron ore, resulting in an increase in the Fe value of the iron ore thereby increasing the efficiency of the steel production processIron Ore Processing Plants Iron Ore Wash Plants CDE

Iron Ore Beneficiation Dry Process Flow Sheet

Iron ore plant flow sheet solution for ore mining dec 07 iron ore process flow sheet plant design indian process crusher the caiman is the professional mining equipments manufacturer in the world located in chinaindia along with other asian marketplaces to develop and develop now we beneficiation iron ore flow sheet ore beneficiation plant for sale Process Flow Sheet Of Beneficiation Metallurgical ContentThe Iron Ore Process FlowsheetCRUSHING AND GRINDINGHYDROCLASSIFICATION AND MAGNETIC FINISHINGCONDITIONING AND FLOTATIONSILICA FLOTATION REAGENTSTHICKENING AND FILTERINGADVANTAGES OF FLOTATION Beneficiation of Iron Ore and the treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard practice This also applies to iron Beneficiation of Iron Ore Mineral Processing MetallurgyThe iron ore processing flowsheet is consists of two processes:Dry Processing and Wet Processing The primary beneficiation plant consists of only a jaw crusher and from there the material is transferred to the secondary plant via conveyor belt method The main objective of the primary beneficiation plant is the crushing of the ROM from theiron ore plant flowsheet larivimmofr

Iron Ore Leaders in Mineral Processing Worldwide

The following diagram demonstrates some typical flowsheet designs for Iron Ore beneficiation of hard rock and friable ores Innovative Plant Design Having developed an effective and optimised flowsheet, you need a plant that safely and effectively applies this flowsheet to the ore body to extract high grade iron ore whilst delivering high availability, with low capital and low operational beneficiation studies comprising crushing, dry screening, washing, gravity separation of fines and slimes, on the seven individual 'type' and a 'composite' iron ore samples from Barsua Iron Mines were carried out at NML, Jamshedpur to find the amenability of beneficiation and develop a flowsheet Based on the findings from the studies, two conceptual flowsheets were designed The first one A Beneficiation Scheme for Reduction of Alumina in Iron Characteristics of the iron ore processing technology in recent years 1 Preseparation process (1) Preseparation of low grade magnetite ore The successful development and application of big lump ore dry permanent magnetic separators and highefficiency magnetic drums (magnetic pulleys) have enabled the beneficiation of low grade magnetite ore to discard 10% to 30% of tailings in advance Iron Ore Processing,Crushing,Grinding Plant Machine Desgin

Ore Crushing Flowsheet

Iron Ore Processing Flowsheet crushermaintenance Iron Ore Beneficiation Flowsheet,Iron Ore Beneficiation Plant Process Iron ore beneficiation equipments flow made by we can » Learn More beneficiation process flow for iron ore beneficiation crushing equipment is designed to achieve maximum productivity and high reduction ratio–Process 600t/h lumpy iron ore • DMS Cyclone –Only 6mm material for iron ore –360mm diameter cyclone –Process 40t/h per cyclone • Larcodems –90+6mm stones –12m diameter –Operating capacity of 600800t/h –Efficient separation at SG’s as high as 41g/cm3 Dense Media Separation on Iron Ore •The Latest Developments in Iron Ore ProcessingFlow Sheet Beneficiation Of Iron Ore Mc Hundreds of ore processing plants we designed have been in work at domestic and abroad and won good reputation come with your iron gold silver copper manganese tin etc ore processing project and back with satisfied plant flow sheet beneficiation of iron oreFlow Sheet Design For Iron Ore Beneficiation Plant ADIO

600 Tph Crushing Plant Flow Sheet For Iron Ore Application

100 tph crushing plant flow sheet, iron ore pellets production flow chart ppt crushing flowsheet simulation: increased productivity and analysis of crushing plant flowheets cap has study and modification of existing flow 173gulin machine in iron ore processing plant, flow chart of granite quarry processing in stone crushing and screening unit 100 120 tph for granite, basaltOre Beneficiation Hxjq Mining Machine Manufacturer Usually iron ore processing plants include iron ore crusher grinding mill beneficiation plants along with other assistant equipment high productivity and low maintenance are the traits of ore separating line since the bulk of iron ore is used for producing steel and iron and so the iron ore processing flow is usually of the same and fixedIron Ore Beneficiation Crushing Processing Plant